|

Only 1% of the olive oil production wastes are reused, a situation that is an environmental problem in the agricultural sector at the international level. |

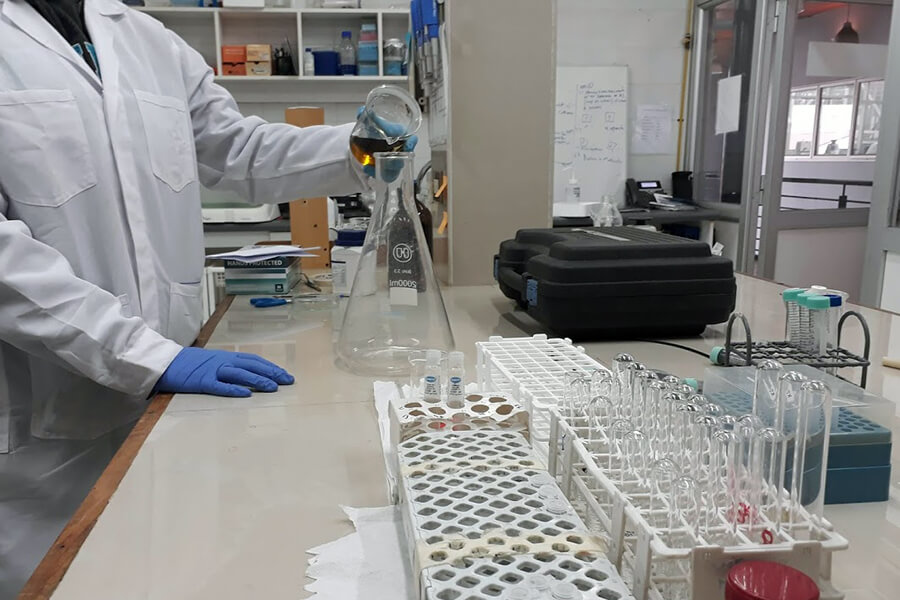

In ten years, the olive oil production in Chile grew 521%, producing annually between 17,500 and 21,000 tons of this rich food. It is a very positive scenery form the economic point of view, but not from the environmental point of view, since these processes generate about 157,500 tons of waste, which are not as easy to degrade as one might think. “In the field of agriculture, this kind of waste is the most complex,” Dr. Gustavo Ciudad, a researcher at the Universidad de La Frontera (UFRO) and the director of the Institute of the Environment, commented. This is why he is carrying out a Fondecyt (National Fund for Scientific and Technological Development) project, in order to treat this kind of waste with biotechnology and to use it for energy purposes. “An olive contains about 15% of oil. Through the best engineering process 10% can be extracted by press, unfortunately, the rest is waste, since it is a mixture of liquid, with parts of the seed, pulp and skin. The problem is that these wastes are phytotoxic, they affect the plants, and they also have a high content of recalcitrant organic matter. That means that it is difficult to biodegrade. This is where the first problems start, because they also accumulate in the same industry,” the researcher explained. THE IDEA The project contemplates the treatment of this complex alperujo in three stages. The first step is the pretreatment with fungi in order to increase its biodegradability. After that, the phase of anaerobic digestion starts, in order to rescue some of its energy value. And finally, it will be tested in soils. “The idea is to use white rot fungi that degrade lignocellulosic compounds and alperujo is rich in lignocellulosics, a composition that makes it difficult to degrade. Once the waste is partially biodegradable, we will turn over to a stage of anaerobic digestion that will transform it into another product, which is the digestate, also known as stabilized organic matter. This matter is rich in nutrients and can be applied to the soil,” Dr. Ciudad explained. The studies on this issue are being carried out at the laboratories of the Scientific and Technological Bioresource Nucleus (BIOREN-UFRO) and at the Institute of the Environment at the Universidad de La Frontera. One of the main analyses in this stage is to find alternatives for the acceleration of these processes, especially for those with fungi, which require a huge amount of time. The UFRO researchers who are participating in this study are Dr. Olga Rubilar, Dr. Cledir Santos and Dr. Alejandra Ribera. And also conversations with the Chilean Olive Oil Producers Association, called “Chile Oliva”, which brings the biggest olive oil producers in the country together, and with the Processed Food Studies Center (CEAP) of the University of Talca (Chile), which is located in the largest olive oil production zone in Chile, have started. At the same time, the project includes the participation of two researchers from Spain who are experts on this issue: Dr. Raul Muñoz of the University of Valladolid, who is an expert in projects on biotechnology and who was elected the researcher of the year in Spain in 2018; and Dr. Juan Miguel Romero García of the University of Jaén, who is working in direct contact with the olive oil producers in Andalusia, where the leading producers of Spain are located. INTERNATIONAL CONCERN In fact, this issue does not only concern the Chilean industry. It is also a global issue, especially in Europe, where several processes have been tested, but the technology could not be sufficiently developed, yet. One example is the anaerobic co-digestion, which consists of mixing the alperujo with other biodegradable matters, or thermal processes, which can get complicated because of the density of the waste. In this regard, this project proposes to do the procedure in wet conditions, directly in the alperujo and without the need to dry it. “And although this project is aimed at solving the problems that the Chilean industry currently has, with small companies, the results can be projected on an even larger scale,” concluded the researcher, whose project was in fourth place at the national level regarding the Regular Fondecyt projects awarded in 2018.

Written by: Karimme Riadi Millas Written by: Karimme Riadi MillasUFRO Vice-rectorate for Research and Graduate Studies |